Do you know that improper shielding gas management can have an impact on weld quality and results? Because it protects the weld pool from pollutants in the air, it must be utilized carefully. Poor gas pressure for mig welding can result in unsightly welds, brittle welds, and porosity.

There are different scenarios for every metal and it depends on the welded metal. Let’s suppose, that mild steel welding with pure Co2 or 75/25 requires 10 – 15 CFH, and in case of any porosity, a 25-30 CFH rate is suggested. So, we have covered all relevant topics related to gas pressure and settings in this article that will help you to understand everything about gas.

Contents

MIG Welding Gas Flow Rate Setting

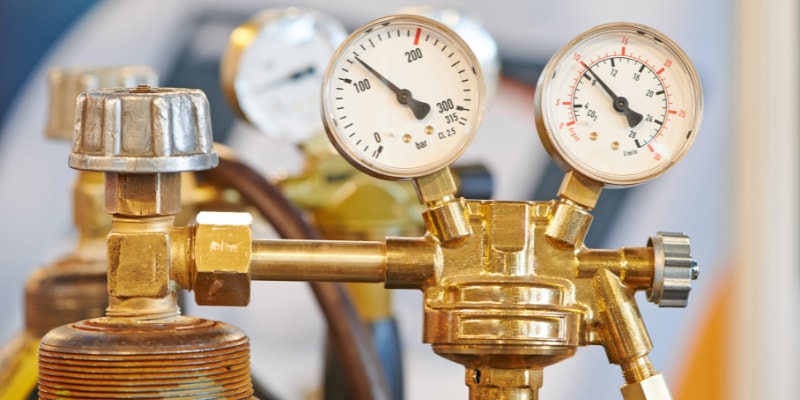

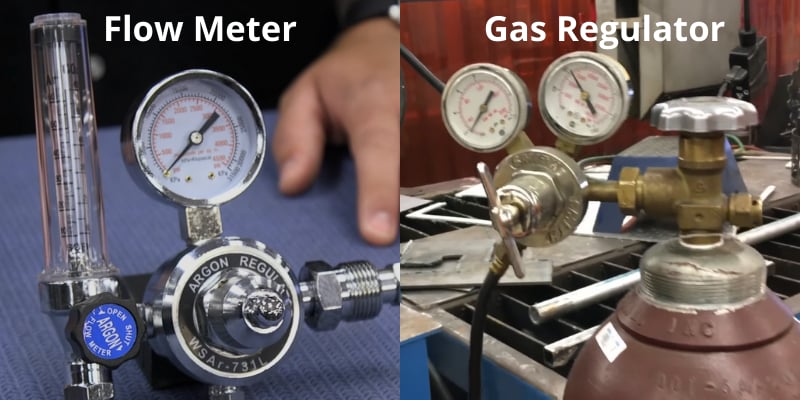

The setting of the gas flow rate is quite simple because gas regulator comes with one valve and two gauges that let you adjust the flow rate. One gauge shows the gas flow rate in cubic feet per hour (CFH) whereas the other one shows pressure in PSI. A valve will release the gas, and the gauge’s needle will indicate the gas flow rate. You may also weld mig without gas by using different settings.

Nowadays, modern or latest regulators come with only one gauge that only shows the pressure and gas flow rate can be checked through the vertical plastic chamber that’s created for them. This chamber has a small metal ball instead of a needle, and all values are written in CFH. When the gas flows through this chamber, the metal ball will go up and you can check the flow rate. You can check this in the below image.

Different Regulators for Gases

You can’t use the same regulator for all gases since they aren’t all of the same mass; some are lighter and others are heavier. As a result, the regulator and the shielding gas must be compatible.

If the regulator is created for any specific gas such as helium or argon, you will get inaccurate measurements if you use any other shielding gas with it. For appropriate and correct flow rate readings, the regulator must be compatible with shielding gas.

Most guys use pure Co2 and some of them faces regulator issue. It’s because of the inappropriate regulators. A low temperature of pure Co2 gas can freeze, so it’s suggested to use a specially designed regulator for it.

Nozzle Size

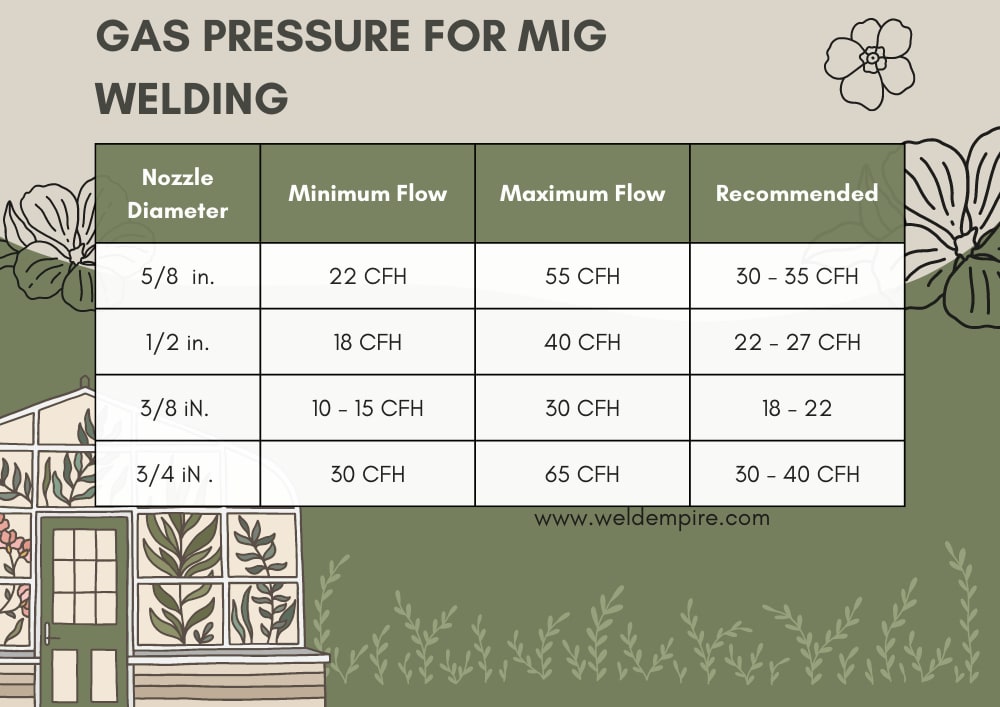

Gas flow varies according to the nozzle diameter. A ⅝” nozzle is used in industrial settings, so the flow rate should be around 30-35 cubic feet per hour. The minimum rate is 22 and the maximum rate is 55 so, don’t exceed this limit to avoid any issues.

Most individuals and hobbyists use a ½” nozzle, the recommended flow rate is 22-27, according to normal welding conditions. The minimum rate is 18 CFH and maximum is 40 and this type of nozzle is used for small and lightweight welding tasks.

Most small units use ⅜ inch mig gun nozzle. The minimum flow rate is 10-15 whereas maximum is 30 CFH. The standard flow rate for these welders is 18-22 cubic feet per hour. Moreover, the flow rate for professional and large industrial welding machines is 30-40 CFH with a maximum flow of 65 and minimum of 30. These units use a 3/4″ mig gun nozzle. MIG Welding gas flow rate chart is given below.

Remember, don’t exceed these limits to protect your weld and shielding gas.

Gas Flow Rate for Different Metals

Mild steel, stainless steel, and aluminum are the most common materials used in GMAW. The flow rate would not be the same for all metals because every material has a distinct wire feed speed, nozzle diameter, and weld travel speed.

Stainless Steel

Stainless steel is a bit technical to weld, so 20-25 CFH is a good point to start. Check the weld surface and quality, if there’s porosity, increase the gas flow rate.

Mild Steel

It’s quite easy and simple to weld. With the pure Co2 or Argon mixture, it’s good to go with 15-20 CFH. In the case of porosity, use the flow rate between 20-30.

Aluminum

Aluminum is an extremely sensitive metal that absorbs heat quickly, hence a fast travel speed is recommended. To have a decent weld, the CFH should be around 30. You’ll need a maximum CFH of roughly 50 if you’re using 25% argon and 75% helium. For mig welding aluminum, the minimum range is 20 CFH.

We have explained the best gas for mig welding and mixtures for different metals, give it a read to clear your confusion.

What is Maximum and Minimum Gas Flow Rate?

There’s a range of maximum and minimum flow rate because breaking the limit could result in poor welds and instability. An excessive flow rate can create trouble and can’t protect the molten pool from contaminants. As explained above, the maximum CFH for aluminum is 50, and if the limit is exceeded, shielding gas will lose the control over weld pool.

Depending on the substance, the minimum flow rate varies. The lowest range for aluminum is 20 CFH, while the lowest range for mild steel is 10 CFH. As a result, it all depends on the metals and other factors.

In comparison to indoor welding, outdoor welding needs a higher flow rate. What will happen if the joint is huge and the wire feed rate and welding speed are both high, but the gas flow rate is lower than the recommended range? With porosity, the weld will most likely be weak.

Common Asked Questions

Both are units for measuring the rate of gas flow. Some units measure flow rate in CFH, whereas others use ‘L/min.’ Most welders now include a gas regulator that uses CFH measurements. As a result, it’s preferred because welding manuals also provide CFH instructions.

The setting is quite simple and easy. Firstly, connect the gas hook with the welder. The gas regulator comes with one valve and two gauges. One gauge is for gas flow rate and another one is for the pressure. The needle will indicate the correct value of gas and pressure.

Last Words

To avoid any problem, use the recommended range of gas pressure for mig welding. You can waste the gas at a high and low flow rate, so you need practice and technique to use the gas carefully. Welders should remember that shielding gas protects the pool from atmospheric gases.

- How to Use a TIG Welder? Ultimate Guide and Expert Tips - March 14, 2023

- What is a TIG Welder? – Everything You Need to Know - March 11, 2023

- Ahp AlphaTIG 200X(updated 203XI) Review for 2023 - February 7, 2023