Last updated on January 9th, 2023

The very first thing during the tungsten inert gas welding is current settings. There are two types of currents: Ac and Dc, and the current settings can change the result, preciseness, and shining of weld results.

There has been debate about Ac vs Dc TIG welding for years. In this article, I’ve covered the most critical aspects of them and attempted to summarize them. TIG welding is not dependent on any specific current, and it depends on the type of metal. Usually, steel is welded with dc and aluminum is welded with Ac.

Contents

AC Welding

Alternating current is an electric current that changes its magnitude with time in contrast to a direct current. During welding in ac mode, the current provided by the inverter operates with positive and negative elements. The combination of one negative and positive element is considered as one cycle.

Arc rectification is the process in which the oxide coating on workpieces stops the electron flow that results in distortion of the positive half cycle. Two types of ac waveforms are listed below.

The Square Waveform

These waveforms are introduced in modern TIG welding machines. In this, positive to negative cycles can be done quickly that results in a more effective current. As shown in the graph, this will enable deep positive (cleaning) and negative (penetration).

When cleaning happens in half of the positive cycle and the other half remains inactive, the electrode can be damaged owing to overheating. Machines with balance controls can help because they allow the time of the positive half cycle to vary within cycle time.

The Sine Wave

Old Tig welders were only sine wave type units. This sinusoidal wave starts from positive cycle zero and goes maximum up and then falls to zero. Current changes its direction to the negative cycle and touches the negative cycle. In this way, one cycle is completed in the sinusoidal wave machines.

DC Welding

The current in direct current GTAW welding moves in only one direction, and there are two methods of dc welding.

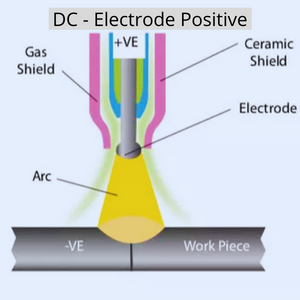

Direct Current – Electrode Positive

The tig torch must be connected to the welding machine’s positive output and the work cable to the negative output in this way. When current is run in a circuit, the positive side of the arc heats up to 67 percent, while the negative side of the arc heats up to 33 percent on the metal side.

You may think, why do we use this method? Because exposure to the atmosphere can cause oxide to form on the metal surface, this oxide contains a higher melting point than others and should be removed before starting the welding.

Direct Current – Electrode Negative

It’s a standard method used for all kinds of materials. In this, we connect the torch to the negative output and cable to the positive output. After the arc is initiated, the negative side of the arc contains 33% heat and the positive side has 67% heat distribution. As a result, we get deep arc penetration into the metal and low heat in the electrode.

Main Difference

Dc is a direct current that flows in only one direction and is widely used for welding all types of steel, cast iron, carbon, etc. In comparison, ac is an alternating current and is primarily used for aluminum welding. In Dc vs Ac welding, many things changes but the core concept remain the same. Same goes for AC vs DC welding, check the article for more exposure.

Why is alternating current used for aluminum TIG welding?

Because aluminum consists of two layers: aluminum oxide that protects the base metal and base aluminum, the Melting point of the base metal is 660.3 degrees, wherever aluminum oxide’s melting point is 2072 degrees. So, the oxide must be cleaned off.

When we apply AC, the current to torch is positive, and shielding gas becomes ionized, which cleans the oxide layer off. This process is named ionic bombardment. Then, due to AC’s cleaning action, aluminum can be easily welded. Additionally, you may use Ac or Dc tig welding for aluminum but again it depends on your skills and the machine’s settings.

Frequently Asked Questions

Q1. Can I weld aluminum with DC?

The best method is to weld aluminum with alternating current. You can weld with some tricks but it’s not recommended.

Q2. Which is more preferable AC or DC?

It depends on your metal. Ac is preferable for aluminum and Dc for steel and other metals

Conclusion

This is all information about Ac vs Dc TIG welding, and I hope you’ve got enough information. Both have their uses and function, one works well on steel, and the other works well on aluminum. For a professional welder, both are necessary.

- How to Use a TIG Welder? Ultimate Guide and Expert Tips - March 14, 2023

- What is a TIG Welder? – Everything You Need to Know - March 11, 2023

- Ahp AlphaTIG 200X(updated 203XI) Review for 2023 - February 7, 2023